The Application of Stepper Motors

A stepper motor is an electromechanical device designed to convert electrical power into mechanical power. If you aren’t overly familiar with motors, it might be difficult to distinguish a stepper motor from another motor type and, more importantly, appreciate the role they play in industrial and manufacturing settings. If you plan on working with motors or devices driven by motors, it’s important to have a firm grasp on why and when a stepper motor should be used, rather than a different motor type. In this article, we’ll define what a stepper motor is, how it works, and the many different uses they have.

What is a Stepper Motor?

Unlike other types of standard electric motors that rotate indefinitely until its power supply is cut off, a stepper motor is a digital I/O type of synchronous direct current motor capable of starting and stopping with precision. It is also aptly named; stepper motors are designed in such a way that the current that passes through the motor engages a series of coils, arranged in phases, that can be turned on and off at high speeds. This unique configuration is what allows the motor to rotate as much or as little as required in order to effectuate the desired action and are often referred to as “steps” (hence the name), since they represent a predetermined series of controlled phases.

From a practical point of view, think of stepper motor design as one that is centered on “breaking up” a typical, full rotation into multiple, equal partial rotations. This means that the partial rotations (which may be defined by a set degree or angle) can be used to actuate very specific movements of components with a high level of precision. As mentioned above, stepper motors are generally controlled digitally and while stepper motor applications may vary, they are typically used for holding and positioning in situations where having the ability to exercise movement control is vital.

How Do Stepper Motors Work?

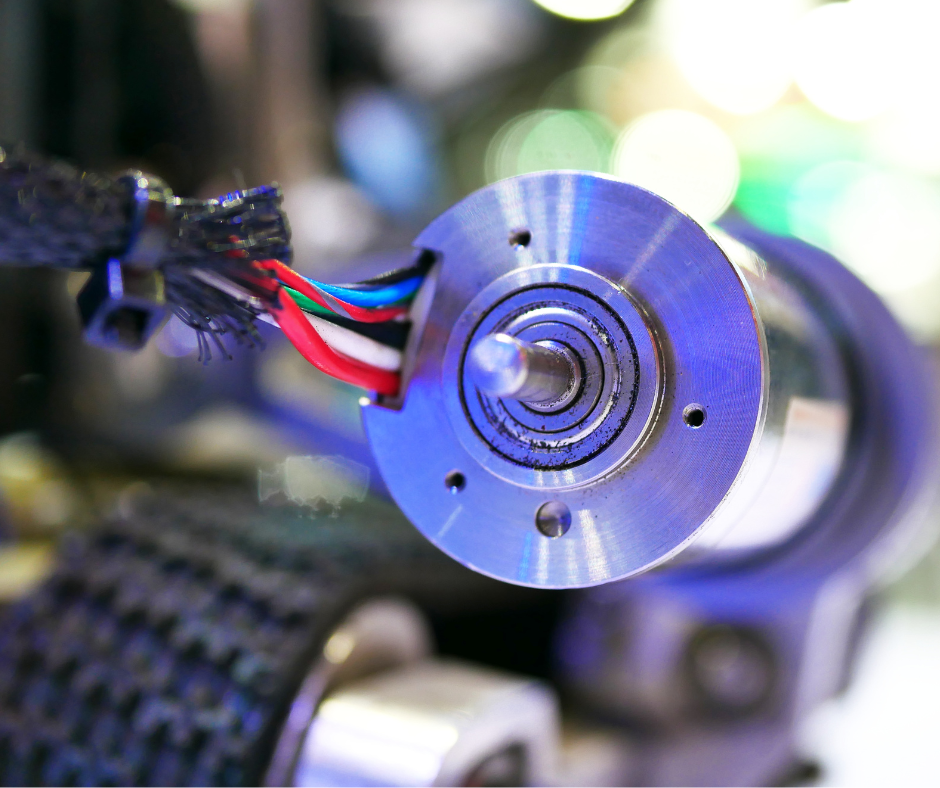

We’ve already described a stepper motor as one that can move discretely and accurately. This is achieved when the stator applies magnetic impulses to the rotor of a stepper motor (thereby creating a rapid push-pull action). The rotor of a stepper motor consists of two discs – one that acts as the magnetic north pole, while the other acts as the south pole. For visualization purposes, think of these two discs as gears that, when placed back-to-back, have alternating magnetically charged “teeth” around the edge (north-south-north-south etc.). Around the edge of the rotor is the stator which consists of a series of electromagnets that can individually be turned on and off. Though they can be controlled individually, electromagnets in the stator generally operate in pairs. For example, two magnets located across from one another will turn on at the same time, creating a north pole at precisely the same moment. When these motors switch off, the other magnet pair switch on, creating a north pole at a right angle of the first pair.

Stepper motors operate quite differently than a typical direct current brushed motor. In this type of motor, voltage is applied to terminals that in turn causes the wire coil to rotate within a fixed magnet housing. The coil at the center of the motor spins rapidly due to the well-known magnetic concepts of attraction and repulsion. Essentially, the wire coil at the center acts as the electromagnet. While this is an effective motor design for most applications, it's not without its drawbacks; for example, the number of rotations performed by the motor is not determined, meaning it will rotate continuously until the supply of electricity is removed. Obviously, such a motor would make it difficult to apply an exact stopping point required by some industrial application of stepper motors. Stepper motors, as we’ve already seen, operate quite differently. Instead of a spinning coil at the center of a fixed magnet housing, stepper motors have a fixed wire housing (the stator) which surrounds the toothed electromagnetic discs that rotate in the center. Since each movement of the stepper motor is controlled by a pulse of electricity, and each “step” is a pre-defined incremental rotation, both full and partial rotations can be completed as necessary with a great deal of accuracy.

Different Types of Stepper Motors

Of course, there are different types of stepper motors that can be used for different applications. In this section we’ll briefly examine the differences between bipolar stepper motors and hybrid stepper motors.

For stepper motor applications in robotics, welding, or printing, a bipolar stepper motor may be used because this type of motor generates more torque (which comes in handy when operating heavy equipment). What differentiates a bipolar stepper motor from the hybrid motor, is the onboard driver that uses an H-bridge circuit. This particular circuit allows the current to be reversed through the phases. Since applying alternating the polarity while energizing the phases allows all coils to be used in turning the motor, the result is greater torque.

If the benefit of bipolar stepper motors is torque, the main benefit of a hybrid stepper motor is precision through actions called micro-stepping. Micro-stepping is achieved by programming the motor driver to send alternating sine/cosine waveform to the coil. Simply put, this technique can be used to further increase the fixed number of “steps” performed by a motor which in turn results in smoother operation of the motor with even greater precision. This type of stepper motor is commonly used by 3D printing machines, textile machines, and medical imaging machinery.

Potential Uses of Stepper Motors

Stepper motors have many different uses across a variety of industries and disciplines. While you may not be familiar with all of them, some of the more common applications are listed below:

- Robotics

- Printing (including 3D Printers) and Scanning

- Computing

- Packaging

- Automation Equipment

- Precision Positioning Equipment

Welcome to the World of Stepper Motors

Without stepper motors, the equipment that we heavily rely on in order to fulfill necessary applications and tasks would not exist. These motors are advanced machines that enable us to work with 3D printing, robotics, cameras, and precision positioning equipment that many electromechanical engineers rely on. If you’re interested in learning about motors or would like to find out more about electromechanical training, be sure to check out George Brown College today.